5 Minute HealthTech Jargon Buster: 3D Bioprinting of Organs and Tissues for Regenerative & Personalised Medicine

- Romilly Life Sciences

- Jun 24, 2025

- 6 min read

By Lathikah Jeevagan, Research and Communications Associate

3D bioprinting is an additive manufacturing technique that builds biological tissues layer by layer using living cells and biomaterials, known as bio-inks [1]. It adapts concepts from traditional 3D printing, originally used for plastics and metals, to deposit cells in elaborate three-dimensional arrangements. This starts with a digital model (often derived from medical imaging like CT or MRI), which is converted into printing instructions for positioning cells and bio-inks. Supported by advances in tissue engineering, biomaterials science, and cell biology, bioprinting offers transformative potential in regenerative medicine and tissue engineering, enabling the fabrication of tissues or organs for repair or replacement.

The Science Behind 3D Bioprinting: Types of Bio-inks

Different classes of bio-inks serve different purposes:

ECM-based bio-inks: The extracellular matrix (ECM) is a protein-rich framework surrounding cells in the body. In ECM-based bio-inks, tissues are decellularised, meaning cells are removed, to leave a structural scaffold (the ECM) [2]. This scaffold is processed into a gel that replicates the natural environment in the body, a feature termed “biomimetic.” Adding stem cells or other cell types guides them to adopt traits resembling the original tissue. For instance, heart ECM bio-ink can prompt stem cells to behave more like native cardiac cells.

Synthetic hydrogels: Synthetic hydrogels, such as polyethylene glycol (PEG), can be finely tuned for properties like stiffness or viscosity. By default, they lack many attachment sites for cells; however, researchers can modify them chemically or blend them with natural polymers to introduce binding spots, boosting cell adhesion and growth.

Cell-only inks and spheroids: Some bioprinting strategies rely on very high cell densities that cluster into small spheroids [3]. These spheroids can be printed directly, with minimal carrier gel. Over time, cells produce their own ECM, forming a cohesive structure that fuses into functional tissue.

Stem-cell-based bio-inks: Stem cells can differentiate into various tissue types. Commonly used are mesenchymal stem cells (from bone marrow or other tissues) and induced pluripotent stem cells (reprogrammed adult cells) [4]. Mixed with a supportive hydrogel, these cells respond to the correct signals to become tissue-specific cells, enabling formation of cartilage, bone, or heart muscle.

The Science Behind 3D Bioprinting: Scaffolding Techniques and Support Materials

Though simple constructs may only contain cell-laden bio-ink, more complex or larger tissues often need extra support from scaffolds [5]. Made from biodegradable polymers (like PLA, PCL, or PEG derivatives), scaffolds preserve structural shape initially, then degrade as cells form their own matrix. Bioreactors - devices supplying nutrients and stimuli - can also facilitate tissue development [1]. Over time, this setup ensures the tissue matures with proper structure and function [6].

The Science Behind 3D Bioprinting: Bioprinting Techniques

Inkjet Bioprinting: Adapted from desktop inkjet printing, this method precisely deposits droplets of cell-laden ink in programmed patterns. Thermal or piezoelectric forces eject picolitre volumes of bio-ink [1]. Inkjet bioprinting is rapid and maintains high cell viability while allowing simultaneous deposition of multiple cell types.

Micro-Extrusion Bioprinting: Here, a continuous stream of bio-ink is forced through a nozzle, guided in three dimensions [1]. This approach accommodates high-viscosity gels, including dense cell suspensions. It is commonly used to fabricate tissues like cartilage or bone and can produce sizeable constructs.

Laser-Assisted Bioprinting (LAB): Concentrated laser energy propels cell-containing droplets onto a substrate. One technique, Laser-Induced Forward Transfer (LIFT), avoids using a nozzle. Another employs light to crosslink photosensitive hydrogels [1]. Laser control allows intricate geometries, including vascular networks.

It should be noted that the choice of method depends on the target tissue requirements: extrusion is preferred for larger, thicker constructs, inkjet for high-resolution patterning and viability, and laser-assisted for complex micro-architecture and precision.

Applications of Bioprinting in Organ and Tissue Regeneration.

Skin Grafts and Soft Tissues

Because skin is structurally simpler than many other organs, it is a prime candidate for 3D bioprinting applications. Bioprinted skin, contains an epidermal layer of cells and an underlying dermal component [6]. Studies have fabricated skin-like sheets, now being tested for wound grafting. Researchers can match a patient’s wound dimensions exactly, and labs (including those of the U.S. Army) have printed muscle patches for major tissue defects [7].

Cartilage and Bone Regeneration

Cartilage consists mostly of chondrocytes and ECM, with no blood vessels, making it easier to print. Potential applications include knee cartilage repair and reconstructive surgery. For bone, blending stem cells with ceramic-like materials (e.g., calcium phosphate) yields partially mineralised structures. Though printing a full human bone is complex, bioprinted bone segments have successfully repaired substantial defects in animal models.

Vascularised Tissues and Organ Patches

Thicker tissues need blood supply. By printing endothelial cells into channels or using sacrificial inks, researchers create “pre-vascularised” constructs. This pre-built network fuses with the patient’s circulation upon implantation. Cardiac patches composed of heart muscle cells and microvessels have shown improved blood flow and functional recovery after heart injuries [6].

Whole Organ Models and Complex Organs

Although printing a fully functional organ for transplantation remains a longer-term goal, smaller organ models exist. Scientists at Tel Aviv University printed a miniature heart containing chambers and vessels [8]. Others have printed lung-like structures or pancreatic tissue, useful for drug screening and disease modelling.

Patient-Specific Tumour Models

In oncology research, 3D bioprinting helps replicate a patient’s tumour by incorporating cancer cells and supportive cells from a biopsy [9]. Companies like Carcinotech create micro-tumour models that preserve the tumour’s architecture, enabling precise drug testing [10].

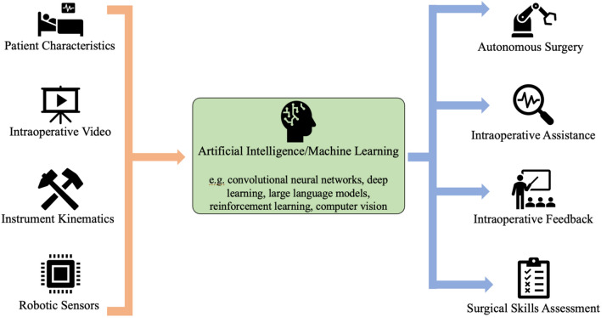

The Role of Artificial Intelligence in 3D Bioprinting

Bio-ink Optimisation

Creating a suitable bio-ink involves finding the right balance of polymers, crosslinking agents (chemicals that firm up gels), and cell density. Machine learning (ML) algorithms can greatly speed this process by predicting the best formulations based on existing data on print quality and cell viability [11]. For example, a neural network might correlate hydrogel viscosity (thickness) with printing accuracy, leading to a recommended formula for an improved bio-ink.

Printing Process Control and Precision

During printing, real-time imaging or sensor data can feed into Artificial Intelligence (AI) algorithms, which instantly adjust dispensing pressure or nozzle speed to maintain consistent layer thickness [12]. This concept, often called “closed-loop control,” ensures precision and uniformity, which are essential qualities for eventually manufacturing clinical-grade tissues.

Design and Structural Optimisation

Beyond controlling the printing process, AI helps optimise the design of the final tissue construct. Computational models can predict how changes in scaffold geometry, like pore size, strand thickness, or cell placement, will affect nutrient flow, cell attachment, and mechanical strength [12]. By rapidly exploring multiple design options, AI guides researchers to the most promising configurations. Deep learning systems also analyse medical images, helping replicate the native anatomy in a printed organ or tissue.

Regulatory Challenges and Ethical Considerations

Because AI-driven bioprinting intersects medical device regulations and advanced therapy medicinal product (ATMP) frameworks, oversight is complex.

Under the European Union’s Artificial Intelligence Act [13] many AI systems in healthcare are classified as “high-risk,” mandating stringent safety and transparency standards.

For bioprinted tissues intended for human therapy, Regulation (EC) No 1394/2007 on ATMPs [14] governs quality and safety. Guidelines from the European Medicines Agency (EMA), such as EMEA/CHMP/410869/2006 [15] for cell-based products, also inform requirements for bioprinted tissues.

The U.S. Food and Drug Administration (FDA), specifically the FDA’s AI/ML Software as a Medical Device Action Plan provides recommendations on ensuring safety and effectiveness through Good Machine Learning Practice (GMLP) [16].

For 3D-printed medical products, the FDA’s guidance on additive manufacturing underscores best practices for design, manufacturing, and testing [17].

Future of 3D Bioprinting in Healthcare

4D Bioprinting and Maturation

A concept gaining traction is 4D bioprinting, where time is the fourth dimension. This refers to printing structures that can change shape or properties over time in response to stimuli (like temperature, pH, or cell-driven forces) [18]. For instance, a tissue could be printed in a compressed form that later expands to its functional shape inside the body, useful for printing an organ that might be too large to print directly in final form due to support issues.

Advanced Bio-inks and Biofabrication Materials

Research is moving toward “smart” bio-inks with growth factors, nanoparticles, or genetic elements embedded. For example, decellularised ECM (dECM) bio-inks will likely become mainstream for each organ type: heart-specific, liver-specific ECM inks, etc. providing organ-by-organ tailored environments [2]. These dECM inks have already shown superior cell function (e.g., printed heart muscle in a heart ECM ink beats more strongly than in generic collagen). As these become commercially available, many labs will adopt them to push functionality of prints.

3D bioprinting represents a convergence of engineering, cell biology, and materials science. By refining bio-inks, perfecting printing methods, and harnessing AI for design and production, this technology brings the medical field closer to customised, functional tissues, and potentially whole organs, that address critical shortages and open new horizons in regenerative medicine.

Romilly Life Sciences can offer several decades experience successfully guiding cutting-edge hybrid technologies through complex regulatory pathways while at the same time generating compelling commercial evidence.

To find out how you can reach patients faster, contact us.

References

[7] https://commons.wikimedia.org/wiki/File:Army_invests_in_3 D_bioprinting_to_treat_injured_Soldiers.jpg

Grant Pharmacy makes it easy to order amoxicillin online with trusted service and quick delivery.

Sanford Pharmacy is more than just a place to fill prescriptions – it is a trusted partner in your healthcare journey. Dedicated to offering quality medicines and reliable services, Sanford Pharmacy combines professional care with a personal touch.